Wafer bisuit production line has different models market, such as the 27 models, 39 models, 45 models, 63 models and so on. All these models production line consist of nearly same parts, one big difference is their wafer biscuit baking oven length are different.

Heating types: Gas and electric can be customized.

Operation:

When the wafer biscuit flour batter gets deposited, the upper and lower baking plates are pressed together and locked. The high closing pressure is absorbed by large size closing rollers located above and below the tongs. Locking is effected by means of hook, and bearing clearance which has no effect on the closing mechanism or on the thickness of the wafer sheet. Batter depositing system ensures uniform sheet weights and waste free and optimum batter usage. Whole baking process about 2 minutes.

Wafer sheet baking plates:

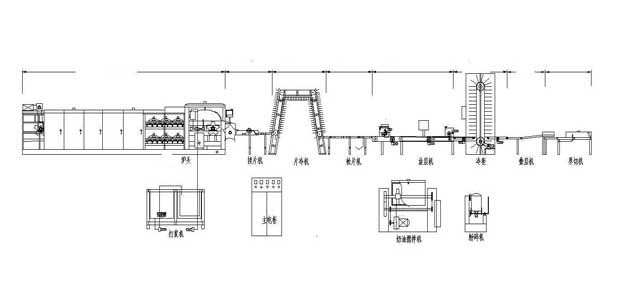

Main machine parts:

1. wafer biscuit batter mixing machine: Mixing materials into batter with large capacity.

2. gas baking oven or electric baking oven: Though high temperature, wafer batter will formed into sheets, size of sheet can be controlled.

3. Wafer sheet connecting machine: Deliver wafer sheet to next working step.

4. Wafer biscuit sheet cooling machine: Cooling wafer sheet for imporve their stability.

5. Wafer sheet collecting machine: Pick out unqualified product, improve products quality.

6. Cream spreading machine: Spreading cream on wafer sheet, wafer biscuit layer according customers' demand.

7. Vertical cooling machine: Quickly cooling wafer sheet down, improve biscuit stability and reduce whole producing time.

8. Wafer biscuit cutting machine: Cutting wafer sheet into the required size( size can be customized).

9. Biscuit smashing machine: Mainly used for smashing unqualified biscuits into powder for recycling usage, reduce materials waste.

Whole wafer bisuict production line flow chart: